This hobby is just one big treasure hunt. You ever just go through the cheap bargain box at your local shop, show, garage sale or wherehaveyou to look for jewels that others may have potentially overlooked? Yea, me neither. Okay okay, so obviously I dig through the bargain bins when I see ’em only because I’ve discovered some uniquely rare items in the past in said locations. I’ve sorted through a lot, A LOT, of cards in my life and one thing is always consistent; there are surprises everywhere.

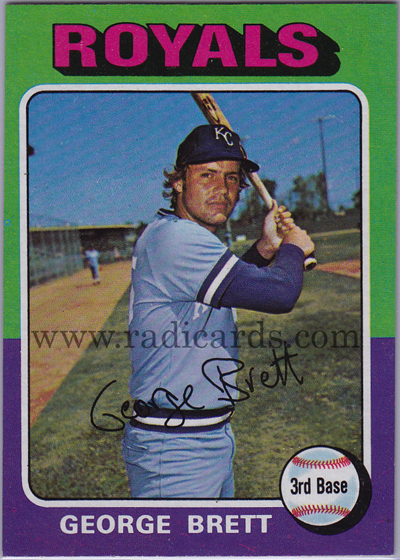

The classic and famous George Brett 1975 Topps #228. Ahh, how I miss the days when players only had just one rookie card. Today, players may have as many as 50+ different rookie cards spread across a carnival of brands and prices. Needless to say, the hobby is much more complex today than it was in 1975. At any rate, this card is the centerpiece of the 1975 Topps set and will go down as one of the greatest rookie cards to come out of the ’70’s. George Brett is a bit of a household name among us baseball enthusiasts. If you’re reading this, I’m assuming you’re familiar with Brett’s talent. If not, here’s a little refresher on Brett’s fielding resume: 13x All-Star, 3x SS, 1x GG, 1x MVP, .305 Career AVG, a member of the 3000 hit club and an induction into the Hall of Fame in 1999. So there you have it, Brett was likely the best player to wear the Royals uniform. Hats off to you Brett!

You’re probably thinking, “what, did he find the Brett RC in the junk boxes?” Surprisingly, my answer is yes but not the strong copy you see to the right. So which one then? Read on…

My discussion is less about the player and more about the card production process. As noted in a previous post on miscuts and Six Sigma, I discussed how the manufacturing process aims for as little scrap as possible to save on costs and maximize quality output. Let’s consider that for a minute, minimize scrap and maximize quality output. That’s the aim and the aim is constant. What do they do with the scrap? Trash it of course. However, let’s not forget the human condition. Sometimes, hopefully rarely, scrap survives the inspection process and makes its way into circulation.

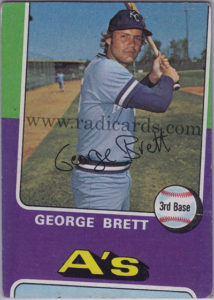

Here’s a more surprising version of George Brett’s RC. I’ve seen scrap but not to this degree. So what the heck happened at the Topps production factory where this could possibly have happened? Why am I looking at this? Why did this card make it to my blog? The following are some possible assumptions:

- Long hours at the plant = human fatigue = increased probability of human error (i.e., the inspector got tired)

- The inspector perhaps consumed one too many beers at the saloon on lunch break. It’s hard to inspect with shaky eyes from intoxication.

- This card was “backdoored” (employee pocketed this card to sell on the secondary market). This assumption is unlikely to have occurred in 1975 but we’ll never know for sure.

- This card was simply overlooked. It happens.

Whatever assumption you adopt, the fact is that it survived. I feel fortunate to have discovered this particular example of Brett’s RC. Just look at this card for a minute, I mean, really look at it! It’s not only severely miscut, it’s also considerably tilted. The combination makes for a significantly asymmetrical design. Asymmetry is somewhat appealing to me and this card is so uniquely obscure that when I first discovered it I couldn’t contain a mild chuckle. How the heck can someone load the 1975 Topps sheets so far off?

In operations management, Poke Yoke is a term that means fail-safing. Poke Yoke originated in Japan in the 1960’s by Shigeo Shingo and was originally used in Toyota manufacturing.1 Poke Yoke is used in lean manufacturing to minimize the chance of human error and make those errors easily recognizable. Poke Yoke devices can be found in daily operations. We are exposed to them everyday. Can you think of one? (hint: size of the diesel fuel nozzle at the gas station). Back to our discussion, it seems that in 1975, the sheet loading process wasn’t accompanied by a guide of any sort. A guide would help minimize or potentially even zero out any chance of miscuting or tilting. The fact that I’m writing about this very card leads me to believe there weren’t any such guides at the Topps factory in 1975. This has to be annoying for the quality control experts assuming of course that there were such things back then. I’m assuming so because miscuts this bad are incredibly rare which could mean that few survived the inspection process.

Whatever the story behind this example, I’m floored that it made it out alive. Stuff like this dies on contact!

Question of the Day:

What could be another assumption as to the origin of the survival of this particular miscut?

To see the current eBay auctions for the 1975 Topps George Brett, click here.

References:

- Poka-Yoke. www.referenceforbusiness.com ↩︎

Have you visited our store? Click here.

Have you visited our store? Click here.

I always thought the clever card companies inserted error cards on purpose in order to create buzz around their product. However, cards like this still don’t make a lot of sense. I love getting errors in newer products since the quality control over at Topps must be ridiculous compared to the 70s and 80s. I recently received the very top of a card that had been cut off when the pack was sealed. I don’t know what player it is, but it’s still cool!

Hi Ryan,

Your thought on manipulation of artificial demand can easily be generalized in today’s market. Today’s so called “errors” are intentionally produced and are mainstream chase cards rather than actual factory mistakes. These are planned marketing plows. Still cool, but don’t fall into the category of scrap. That card you received sounds interesting and would probably fall into said category. Great find! 🙂