The time has yet again come to share the feel of frosty weather that only December can provide. Another year passes and I’m not alone in the reflection of time gone by. This year has provided me with a great deal of lessons learned and once again I am reminded that I am human. As humans, it’s expected that we make a few mistakes along the way. Mistakes are often paired with a period of introspection. This is the same introspection that breads questions such as: What are my mistakes?; Am I the only one that identifies my actions as mistakes or are there others that share similar feelings?, and finally, What can I learn from my mistakes? Questions that require a modest and open mindset.

Some mistakes go unrecognized, even hidden from the public. In this hobby, I am often reminded that I am yet to be exposed to novel errors. Just when I think I’ve seen it all, I find myself in the most vulnerable position to be blown away by the surprise of a new discovery. This week, a reader sent me some interesting information regarding an intriguing example of yet another unknown production scrap escapee.

To my knowledge (don’t quote me) but my initial understanding of the basic premise behind the general production and manufacturing cycle of baseball cards progresses along something like the following lines:

- Large blank sheet is loaded into the printing press

- Large blank sheet is then printed first with black, then with color

- Large sheet now becomes a large uncut sheet of baseball cards

- Large sheet is cut into 2-1/2″ x 3-1/2″ individual cards

- Individual cards are packaged, distributed and sold accordingly

Consider the steps for a moment, then take a look at this card from 1993 Upper Deck:

Take another look at the card pictured, really look at it. Where the heck does this card land in the production cycle?! If this process is in fact accurate the card you see here shouldn’t exist. The fact that it does leads me to adopt one of two options:

- My understanding of the production cycle is flawed;

- Something happened as some point during the production phase that skipped a step in the process

So what the heck happened here? Let’s assume that this was in fact an unintentional error. With that in mind, let’s rewind to step #1 regarding the sheet loading process. During this phase, I’m going to propose a hypothesis:

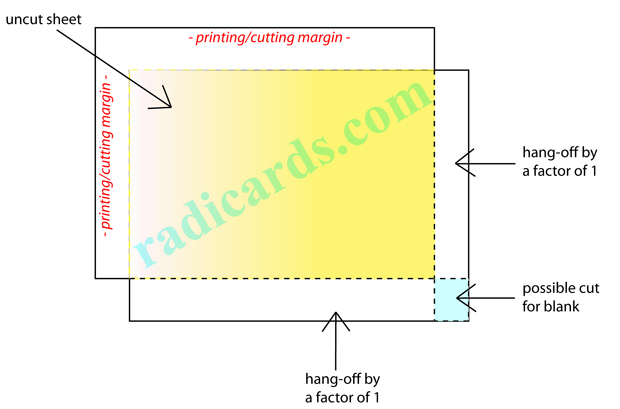

The sheet was loaded in such a way that a portion of the sheet was hanging off, possibly off by a factor of 1. For example, let’s say the sheet is 10 cards wide and 12 cards long. There are two cuts: length and width. The lengthwise cuts will be 12 cards long and the widthwise cuts will be 10 cards long. Let’s assume now that the sheet was loaded in such a way that a 12″ and a 10″ cut was hanging off the edge of the cutting margin. Review the following illustration for clarification:

Illustrated Theory:

The yellow box denotes the production print/cut margin or area. This is the area intended for the uncut sheet to be placed or loaded. Note the hang-off on the right and bottom axis’. This is the portion of the sheet that wasn’t exposed to the cutting and printing process. The dotted lines represent cut lines. On the lower right hand corner, you’ll see a lightly shaded box; this could potential be the cut that resulted in the production of this card. This is the portion of the sheet that potentially could have created the blank card you see here. Depending on how many sheets were loaded in this way, there may be other such cuts, how many survived the process is the big question. Is this the only one or are there others?

This theory would nix the probability of this card ever experiencing the feel of ink which in turn would account for its blank sides. This card made it past the print stage unscathed but somehow made it through the same cutting phase as the rest of the sheet. This is the part that confuses me. If this card had been cut, it would have been easily identified by quality experts and trashed. If I were the quality expert and I saw a long strip of blank uncut cardboard, I would be alarmed and immediately attempt to identify the origin of the mistake. What boggles me is that it was cut from a strip that didn’t even make it into the cutting quadrant. This proposed conclusion is only admissible in the event that my hypothesis is correct. Truthfully, I have no idea how this card materialized. That fact alone safely holds my interest.

Whatever the case, I can vouch for the majority here by saying that this card wasn’t intended for public consumption. And rightly so. If I bought a pack of 1993 Upper Deck and all cards looked like this, I would either feel ripped off or experience the extreme urge to run out and invest in a pile of lottery tickets. Each experience is of course, personality specific. On one hand, the entitled collector would likely experience resentment toward Upper Deck for slighting the customer with what we’ll safely call, “fake outs”. On the other end of the spectrum we have collectors who understand that which falls strongly to the right of the 99th percentile of the normal distribution curve is in fact something of an anomaly and hence holds significance by brute force alone. These are the same collectors that find these outliers as the enhancements that keep them driving and maintaining interest. It’s these outliers that provide an army strong barrier against any probability that will have us abandoning the hobby. In English, as long as there are errors like this out there to be discovered, I will continually be an interested and involved collector. This again has me wondering… what else is out there?

I would like to thank William Dugger, the owner of this card, for reaching out to me and supplying pictures of his card. If you have any information on the origin of this mystery, I would love to hear your thoughts and I’m sure William would like to know as well.

Question of the Day:

If pro and con are opposites, wouldn’t the opposite of progress be congress?

To shop for cards from 1993 Upper Deck, click here.

Have you visited our store? Click here.

Have you visited our store? Click here.

Have you ever seen an error like this one?

http://josecanseco.webs.com/apps/photos/photo?photoid=43723351

Jamie

Jamie,

Now there’s a pretty nice little error. I actually haven’t seen that card. Love that there’s a hologram on the front! That’s rad! Epic find 🙂

I told this guy to contact you, it was on beckett and I thougt you’d like to do a post on it. I love the way blogs make the world a little smaller and I’m happy to see it worked out. Sweet canseco btw.

Jason,

That was you? Excellent work! Big thanks for the lead. 🙂 Yea, Jamie’s Canseco error adds a nice little touch to his collection. Feel free to share your errors on here Jason.

I’ll dig through some of my old cards from by youth when I see the parents again for the Christmas holiday. I know I have a couple odd errors cards that I never got good info on.

Jason,

That sounds good; I look forward to seeing what you dig up. 🙂

Thanks JBob,

I found it in a Canseco lot I bought on ebay in the late 90’s. I’ve never seen another but I keep looking.

Jamie

Jamie,

I wonder if Thomas made it out with a hologram on front like your Canseco. I’m not sure if all cards in the set share that variation. It’s possible but nobody knows for sure.

Sorry I got behind here but Patrick thanks again for the help with the hat! I also got the bat and love it! Jamie I’d like to say i’ve been to ur site in the past and ur collection is crazy awesome it’s nice to hear from you. We Canseco fans can be few and far between.

Jason,

No problem, I’m glad that the hat made it to you safely! I’m also glad I could help connect some fellow player collectors. 🙂

Hi Jbob,

Glad you enjoyed the site. There’s not a lot of us Canseco fans but were all die hard about collection completion.

No complicated theory needed, just a simple human mistake.

In the printing process of trading cards, printers run a few hundred sheets through the press to check for ink density, color, registration, etc…, before the actual cards are printed. These “test sheets” are called “make-readys” These sheets, once approved, are then discarded and shredded.

The process of foil stamping (of which the holograms are) is a totally separate process, utilizing different equipment. Make-readys are also run to check for registration (position) and foil adhesion. Again, these sheets, once approved, are discarded and shredded.

So, how do these error sheets end up in the production run? Very simple. A pressman, or for that matter, anyone doing the “press-check” puts the make-ready sheet on the wrong pile – the pile intended for production. With many palettes containing stacks of cards in various stages of production, one can see it would be very easy to accidentally place a make-ready sheet on the wrong pile.

Once printed and foil stamped sheets are done, they are loaded into automated cutting machines and off to packaging they go. Very few human eyes see the thousands of cards being packaged, as it’s all automated.

Wow! That makes a lot more sense than my proposed theory. Huge thanks for this info. I’ve been wondering about this since I discovered this cards existence. The info you’ve provided sheds significant light on the matter. I’ll contact the owner of the card and let him know. Thanks for stopping by, taking a read and sharing the info. 🙂